We regenerate batteries for forklifts

For optimal performance and service life: We regenerate your weak forklift batteries

Regeneration of forklift batteries: Your advantages

- You save compared to buying new

- Extending the service life

- Increased efficiency

- Environmentally friendly

- Performance improvement

- Resource efficient

- Reducing operating costs

- Sustainable

How regeneration works

-

Careful analysis for maximum efficiency

Our regeneration process begins with a precise diagnosis of your battery. We identify performance issues like sulfation and lay the foundation for successful regeneration.

-

Effective removal of deposits

Using state-of-the-art technology, we clean the battery cells and remove sulfate crystals. This improves capacity and extends the lifespan of your battery.

-

Optimized battery performance

After regeneration, your battery is once again powerful and durable – for less downtime and reduced operating costs.

Forklift battery regeneration: How regeneration works

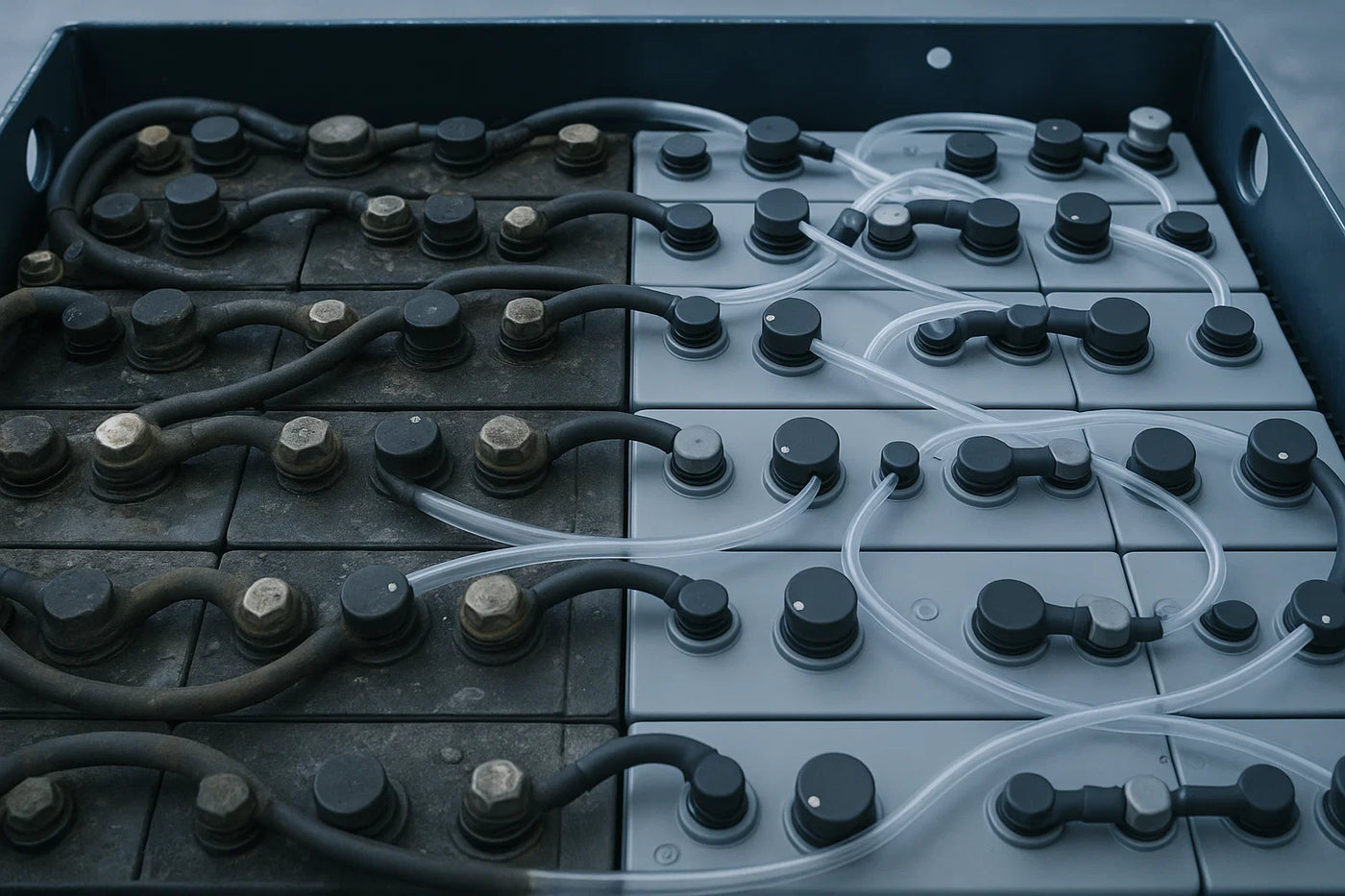

The forklift battery regeneration service from HK Handels GmbH is a special process for optimizing the service life and performance of your forklift batteries used in industrial trucks. Through a thorough diagnosis, we first determine the current condition, paying particular attention to sulfate crystals on the electrodes. This sulfation can significantly impair performance.

After diagnosing and determining whether battery regeneration is necessary and advisable, the actual regeneration process begins. Using state-of-the-art technologies and processes, we clean the battery cells of harmful deposits, especially sulfation on the electrodes, and restore their maximum possible capacity. The result: a more powerful forklift battery with a longer service life and thus lowers your operating costs. Rely on our expertise and comprehensive service for battery regeneration for electric forklifts and other industrial trucks.

Advantages of regenerating forklift batteries

Forklift battery regeneration offers companies a great opportunity to reduce operating costs while minimizing their environmental impact. Extending battery life not only saves you money but also reduces environmental pollution. It also reduces downtime for your material handling equipment, increasing productivity and improving the overall efficiency of your operation. With our professional regeneration, you reap the benefits and can rely on a reliable and sustainable power source.

Forklift battery: regeneration vs. new purchase

Our regeneration service effectively extends the lifespan of your forklift batteries while helping you use resources wisely. We are committed to sustainability and want to give you the opportunity to make optimal use of existing resources. In contrast, while purchasing new batteries may offer short-term benefits, it often comes with higher costs and environmental impacts. As an experienced company, we help you make the best possible decision in this area. We ensure that your operating costs are reduced and your environmental impact is minimized.

More than just regeneration of forklift batteries – Sales & Service

At HK Handels GmbH, we offer more than just forklift battery regeneration. Our comprehensive service portfolio is designed to maximize the service life and efficiency of your forklifts.

In addition to regeneration, we also offer new, used, and tested traction batteries for sale – whether for sideloaders, pedestrian stackers, tractors, towing vehicles, front loaders (forklifts), or other industrial trucks. Our product range includes a wide range of battery types and sizes to ensure optimal performance for electric industrial trucks and pallet trucks.

Our goal is to offer you a holistic service that goes beyond simply regenerating your forklift battery.

Capacity tests: Testing according to DIN (I5) standard C5 test

Our battery service includes not only checking the residual capacity but also a thorough capacity test according to DIN I5 (C5 TEST). We also have the ability to test according to I10 or I20 (C10, C20), depending on your requirements. These essential tests allow us to check the residual capacity of various battery types, including traction batteries. With our specialized testing procedure, we can not only determine the current condition of each battery but also predict how it will behave in the future. Forklift battery aging is an unavoidable process in which the battery loses performance due to factors such as electrode sulfation, which causes sulfonated deposits to form on the surface of the battery cells. These effects can be significant and impair the battery's service life and efficiency.

Our tests help identify such problems early on, allowing you to play it safe when purchasing our batteries. Upon purchase, you will receive a detailed test report that provides a clear picture of your battery's performance and the potential effects of aging on it.